A Comprehensive Overview to Heat Transfer Fluid for Solar Thermal Equipments

Why Heat Transfer Fluid Is Necessary for Optimizing Energy Transfer in Solution

The role of heat transfer liquids in optimizing power transfer is pivotal for achieving efficient thermal administration across different industrial sectors. These liquids promote smooth warmth exchange, making sure procedures run within optimal temperature arrays and mitigating the threat of getting too hot.

Duty in Thermal Monitoring

Warmth transfer liquids play a vital function in thermal administration by effectively managing temperatures in various commercial procedures and systems. These specialized fluids promote the transfer of heat in between various components, ensuring optimum operating problems and avoiding overheating. By keeping exact temperature control, warmth transfer liquids enable sectors such as chemical production, oil and gas, and power generation to operate securely and effectively.

The choice of an appropriate warmth transfer fluid depends on numerous aspects, including thermal security, heat capacity, and thickness. High thermal stability makes certain that the fluid can endure severe temperatures without degrading, while a high warmth capability allows it to take in and launch considerable quantities of warm - heat transfer fluid. Reduced viscosity lowers the energy needed for pumping, adding to general system effectiveness

Moreover, heat transfer fluids are integral in applications like refrigeration, where they help absorb and dissipate warm throughout the cooling cycle. In solar thermal energy systems, these fluids capture and transport solar heat to produce electrical energy or give warm water. Their versatility to diverse operating conditions and ability to maintain regular thermal efficiency underscore their value in industrial thermal administration, promoting operational connection and enhancing security actions.

Enhancing System Effectiveness

To take full advantage of the advantages of thermal administration, boosting system effectiveness via the tactical usage of heat transfer liquids is vital. These liquids play a vital duty in optimizing power transfer by facilitating constant thermal law, which in turn impacts the total performance and durability of systems. Reliable heat transfer results in lessened power losses, reduced operational prices, and boosted reliability of devices. By preserving optimum temperature levels, warm transfer liquids aid make certain that systems operate within their developed specifications, therefore preventing overheating and minimizing the threat of element failure.

Kinds Of Warmth Transfer Fluids

The diversity of warmth transfer fluids highlights their vital role in a series of industrial applications, each tailored to fulfill details thermal monitoring demands. These fluids help with efficient power transfer and are picked based on essential residential properties such as thermal stability, viscosity, and warmth ability. The main types consist of water, glycol options, oils, and synthetics, each offering unique advantages.

Water is the most usual heat transfer tool due to its high particular heat capability check out this site and low price. Mineral oils are favored for their thermal security and non-corrosive nature, making them appropriate for high-temperature applications.

Artificial fluids, including silicone and fragrant substances, give outstanding thermal security and are made use of in environments requiring severe temperature ranges. These fluids make sure premium performance in systems where conventional fluids might fail. The selection of a heat transfer fluid is vital, as it influences system effectiveness, security, and long life. Each kind has to be picked to straighten with the functional needs and the certain problems of the application it offers.

Environmental and Economic Conveniences

Utilizing the appropriate warm transfer liquids provides significant environmental and financial advantages for commercial operations. Ecologically friendly warm transfer liquids, typically biodegradable and non-toxic, decrease the risk of dirt and water contamination in the event of leaks or spills, therefore safeguarding ecological communities and conforming with rigorous environmental guidelines.

Financially, the best warm transfer fluid can considerably lower operational expenses. Reliable heat transfer decreases power expense, resulting in reduced energy costs and improved earnings. In addition, fluids with extensive lifecycle efficiency decrease the frequency of replacements and maintenance, lowering downtime and associated costs. Investing in premium liquids can also reduce the threat of equipment corrosion and failure, preventing expensive fixings and extending the lifespan of vital framework. get more In competitive markets, these cost savings and effectiveness supply an unique advantage, enabling business to assign resources better and purchase further development. In general, the strategic use optimal warmth transfer liquids sustains sustainable economic growth and ecological stewardship.

Picking the Right Fluid

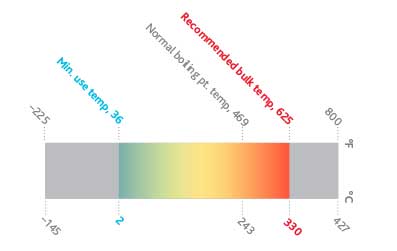

How does one browse the complex procedure of picking the best warmth transfer fluid for industrial applications? Choosing the suitable liquid is vital, as it directly affects system effectiveness, safety, and functional costs. Trick considerations include thermal security, compatibility with system materials, and operating temperature level range. Thermal security guarantees the liquid can endure heats without deteriorating, while compatibility protects against corrosion or other destructive reactions with system elements. The operating temperature level range should straighten with the system's needs to maintain performance and durability - heat transfer fluid.

Furthermore, the liquid's warmth ability and thickness are extremely important. A high heat capacity allows the fluid to absorb and transfer more energy, enhancing efficiency. Optimum thickness makes sure very little pump job and reliable warmth transfer, specifically in differing temperature levels. Environmental and security elements ought to also become part of the decision-making procedure. Safe, naturally degradable liquids minimize environmental effect and follow regulative requirements, reducing obligation risks.

Verdict

The tactical option and application of heat transfer liquids are fundamental to maximizing energy transfer across different systems. By guaranteeing high thermal security and capacity, these fluids give precise temperature level control and enhance overall system performance.